The Refrigeration Cycle & its Basic Components Explained

A refrigeration system is a collection of components that work together to move heat from one area to another. The most common type of refrigeration system is the air-conditioning system, which is used to cool air in a building. Other types of refrigeration systems include those used in food processing and storage, medical laboratories, and motor vehicles.

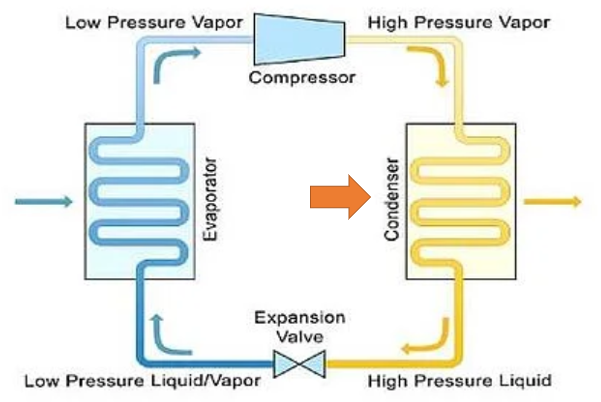

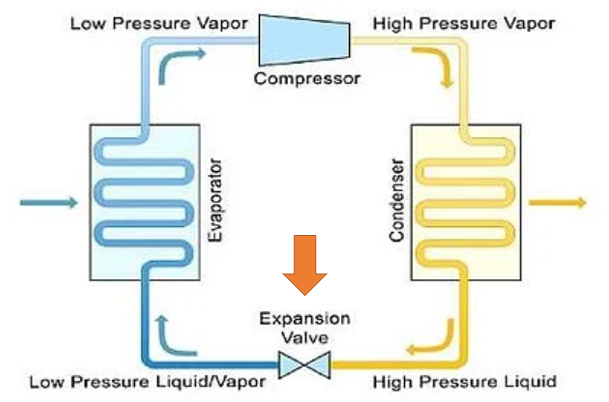

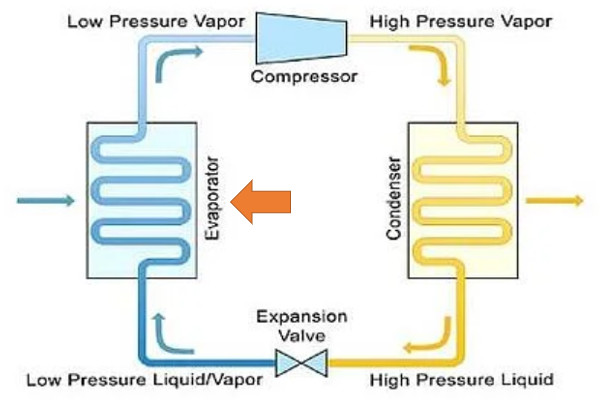

What is The refrigeration Cycle?

The refrigeration cycle is the process of moving heat from one place to another in order to cool down a space or object. In most cases, the goal is to move heat from inside a fridge or freezer so that the temperature inside stays cold, while the temperature outside stays warm.

The refrigeration system basic components

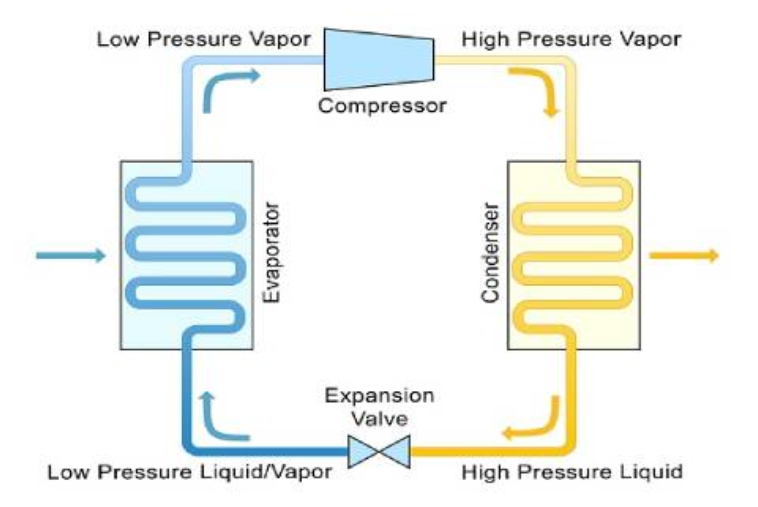

The basic components of a refrigeration system are a compressor, a condenser, an evaporator, and a controller.

The compressor pumps refrigerant through the system. The condenser removes heat from the refrigerant and releases it into the air. The evaporator absorbs heat from the air and transfers it to the refrigerant. The controller regulates the flow of refrigerant and controls the temperature of the system.

The compressor

The compressor is the heart of the refrigeration cycle. It is a pump that circulates the refrigerant through the system. The compressor increases the pressure of the refrigerant, which in turn increases its temperature.

The hot refrigerant then flows through the condenser, where it is cooled and turned back into a liquid. The liquid refrigerant then flows through the expansion valve, where its pressure is reduced. This causes the refrigerant to expand and cool.

The cold refrigerant then flows through the evaporator, where it absorbs heat from the surrounding air and turns back into a gas. The gas then flows back to the compressor, and the cycle begins again.

There are three main types of compressors: reciprocating, scroll, and rotary. Reciprocating compressors are the most common type used in household refrigerators.

They use pistons to compress the refrigerant. Scroll compressors are more efficient than reciprocating compressors, but they are more expensive. Rotary compressors are the most efficient type of compressor, but they are also the most expensive.

The compressor is one of the most important components of the refrigeration cycle because it is responsible for circulating the refrigerant. Without the compressor, the refrigerant would not be able to flow through the system and the refrigerator would not be able to cool.

The condenser

A condenser is a device or unit used to condense a substance from its gaseous to its liquid state, by cooling it. Condensers are used in both air conditioning and refrigeration systems. In order to work, the condenser must be placed in an area where the temperature is lower than the temperature of the substance being condensed.

The most common type of condenser is the air-cooled condenser, which is used in most household air conditioning units. The air-cooled condenser consists of a metal coil filled with Freon. The Freon is cooled by the surrounding air, causing it to condense into a liquid.

Another type of condenser is the water-cooled condenser, which is often used in industrial refrigeration systems. The water-cooled condenser consists of a metal coil filled with Freon. The Freon is cooled by circulating water, which causes it to condense into a liquid.

The third type of condenser is the evaporative condenser, which is used in some air conditioning and refrigeration systems. The evaporative condenser consists of a metal coil filled with Freon. The Freon is cooled by evaporation, which causes it to condense into a liquid.

The fourth and final type of condenser is the absorption condenser, which is used in some industrial refrigeration systems. The absorption condenser consists of a metal coil filled with Freon. The Freon is cooled by an absorption process, which causes it to condense into a liquid.

The expansion valve

To prevent this liquid from being forced out of the evaporator, a device called an expansion valve is used. The expansion valve regulates the flow of refrigerant into the evaporator, keeping it at a constant level.

The expansion valve is controlled by a thermostat, which turns it on or off based on the temperature of the air around the evaporator. When the thermostat senses that the temperature is too high, it turns on the expansion valve to allow more refrigerant into the evaporator. When the temperature is lowered to the desired level, the thermostat turns off the expansion valve to prevent too much refrigerant from entering the evaporator.

The expansion valve is an important part of any refrigeration system, as it helps maintain efficient operation and prevents damage to your home or office.

The evaporator

In a refrigeration system, the evaporator is the component in which the refrigerant absorbs heat from the surrounding air, causing it to evaporate. The evaporator is typically located inside the home or building being cooled and is connected to the outside via refrigerant lines. The evaporator is usually mounted on or near the cooling coil of an air handler or blower coil, where it can receive cold air from the cooling coil.

The evaporator works by absorbing heat from the air around it and turning the refrigerant inside it into a gas. This process removes heat from the air, lowering its temperature. The colder the evaporator, the more heat it can remove from the air.

The refrigerant used in the evaporator must have a low boiling point so that it can easily turn into a gas at relatively low temperatures. The most common refrigerant used in residential and light commercial evaporators is R-22, which has a boiling point of -40 degrees Fahrenheit (-40 degrees Celsius).

When the refrigerant reaches its boiling point, it turns into a gas and begins to expand. This expansion causes the pressure inside the evaporator to drop, which in turn causes the compressor to work harder to maintain the correct pressure balance. As the compressor works harder, it uses more energy, which increases your utility bills.

The expansion of the refrigerant also causes some of the liquid to be forced out of the evaporator and into the surrounding air. This liquid then condenses on any surface it comes into contact with, including your walls, ceilings, and floors. This condensation can lead to mold and mildew growth, as well as water damage.